Did You Know?

Monroe County Water Authority’s water is a great value – approximately 1¢ for 4 gallons – delivered to your home

“For nearly two years, 165 feet beneath the surface of Lake Ontario, a giant ‘mole’ steadily carved a one-mile long, nine-foot diameter tunnel through solid bedrock.”

That may sound like the coming attraction for a new science fiction motion picture, but it accurately describes a key part of the Monroe County Water Authority’s East Side Water Supply Project that, like a good sci-fi movie, also challenges one’s imagination.

Beginning in mid-2013, the giant tunnel began drawing up to 50 million gallons a day of fresh lake water for the new Webster Water Treatment Plant, now co-exists with the west side Shoremont Treatment Plant to supply water to the Authority’s 50 area communities.

This second major source of Lake Ontario water provides added reliability and critical redundancy to our community’s main supply of fresh water, achieving a goal initially envisioned in the 1950s. With the new plant online, planned or unplanned maintenance and repairs can be made without relying exclusively on water stored in the Water Authority’s carbon footprint.

Having treatment plants on both sides of Monroe County also eliminates the need for several substantial booster pumps that have been used to deliver water to the east side. Basically, the two-source configuration means that water need only be pumped half as far as in the past, which reduces costs, helps keep water rates affordable, and significantly reduces both energy consumption and the Water Authority’s carbon footprint.

How it Works

As the water is drawn from the intake tunnel system, it passes through several screens to separate out fish and other foreign matter. It is then pumped three miles south through a 48-inch main to the Webster Water Treatment Plant, where state-of-the-art technology is applied to assure the water meets exacting standards for quality, purity and clarity.

As an initial step at the plant, chemicals are added to the water in tiny quantities – literally one drop at a time. In this coagulation process, alum (aluminum sulfate) and polymers attract impurities and help them to form clumps called “floc” that are large enough to be captured by the filters. Chlorine is added to sanitize the water and carbon dioxide is used to appropriately adjust the pH level.

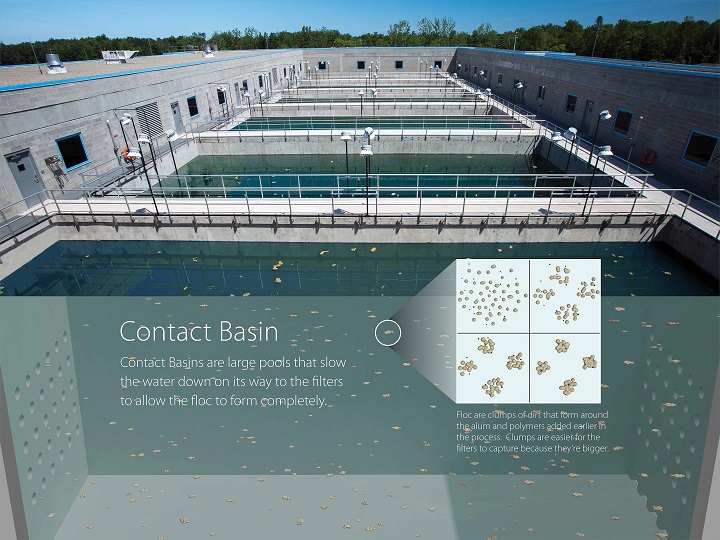

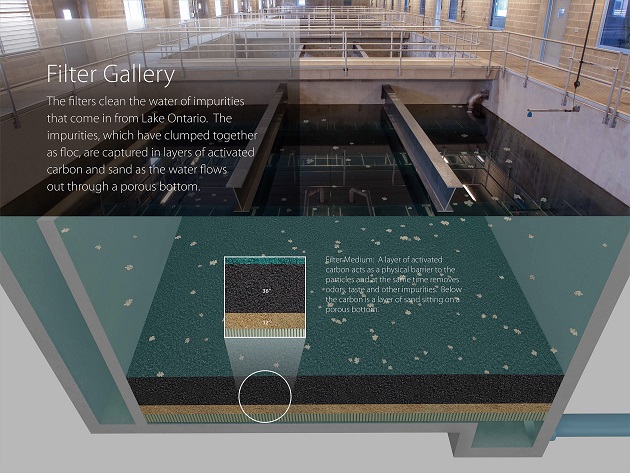

Before reaching the filters, the water enters large pools called contact basins. Here, the floc is allowed to form completely before moving on. From the basins, the water flows through filters composed of layers of sand and activated carbon. The floc is captured as the water flows out through a porous bottom. The activated carbon not only provides a physical barrier to the particles, it also removes odors and other impurities.

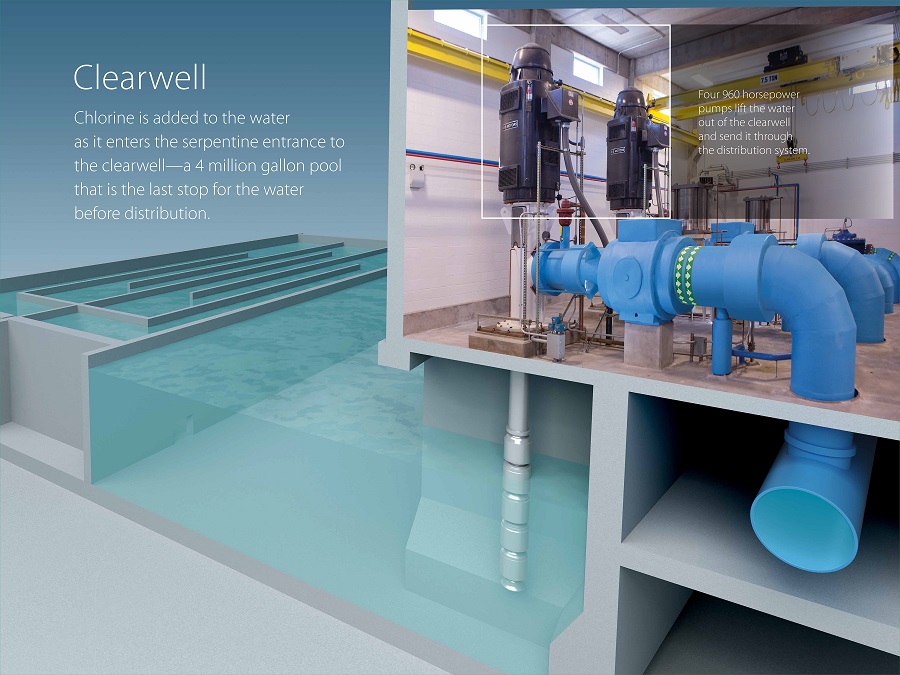

A final application of chlorine is then added to the water as it moves through a serpentine entrance to a four-million gallon pool called a clear well. This further sanitizes the water, kills any surviving germs, and keeps the water clean over time.

Water is tested daily in an on-site laboratory to ensure the standards are met, and results are reported to the Monroe County Health Department. Once the water properties are verified, it is pumped into some 10 miles of new water mains and transmission facilities that connect the plant to the distribution system.

Going Green

From construction to operation, the Webster Water Treatment Plant stands as a “green” facility that respects the environment.

Consider these facts:

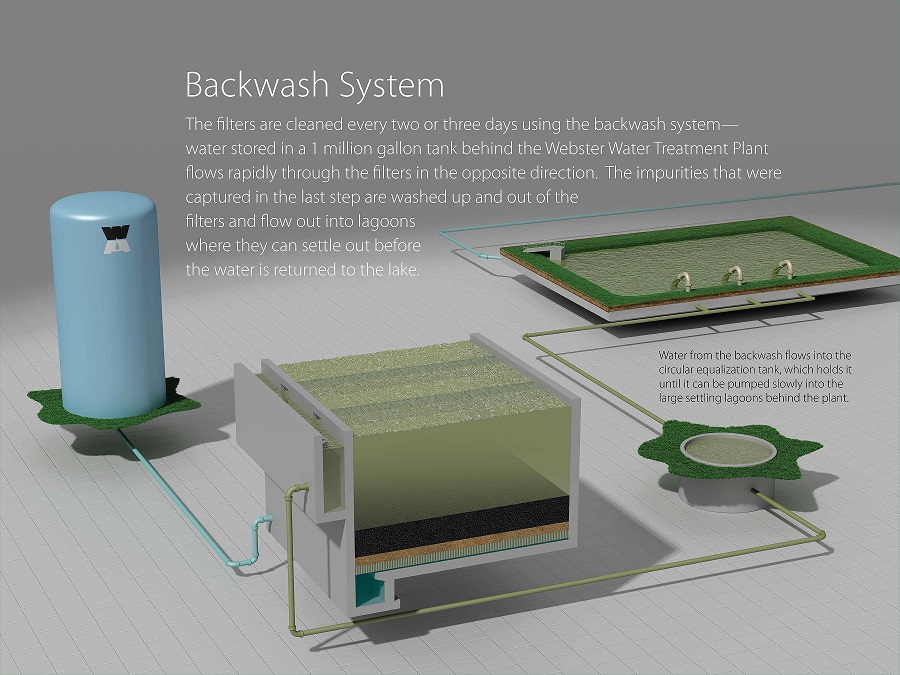

- The one million-gallon backwash tank used every few days to clean the filters is re-used from a previous installation, amounting to 155 tons of recycled steel.

- The 13 miles of new transmission mains are made of 75 percent recycled ductile iron and 50 percent recycled steel.

- The east side location of the plant reduces by one megawatt (one million watts) the energy needed to distribute water to MCWA communities.

- The plant takes advantage of the region’s often-cold temperatures by using a natural freeze-dry process for treatment of backwash sludge. Instead of highly energy-intensive conventional treatment methods such as presses or centrifuges, each winter the settled backwash residuals are spread in a thin layer and allowed to freeze. This breaks the bonds of hydration and allows the particulate material to separate and settle as the water is returned to the lake. The annual energy savings of this process are well above 100,000 kilowatt hours.

- The project included creation of ten acres of wetlands in Webster.

- Larger intake and transmission mains reduce the long-term energy requirements and electrical demands.

- Naturally chilled lake water is used to cool the plant, reducing cost and energy consumption.

Funding the Project

The Water Authority began to address the financial requirements needed for the $150 million East Side Water Supply Project in 1995 by establishing a cash reserve fund. By the time the first construction contracts were awarded, the fund had cash reserves in excess of $20 million dedicated for this purpose.

The sound economic case and the green aspects of the project helped immensely in acquiring federal stimulus funds and outside grants and financing. Through the American Recovery and Reinvestment Act, for example, the New York State Department of Health awarded the Water Authority grants and subsidies, in large part because the project followed energy-efficient green practices.

Other sources of funding and financing included:

- $17.75 million grant from the American Recovery and Reinvestment Act of 2009

- $17.75 million in low-interest financing arranged by the New York State Environmental Facilities Corporation and underwritten by the American Recovery and Reinvestment Act of 2009.

- $5.76 million grant from the United States Environmental Protection Agency.

- $100,000 grant from the New York State Energy Research and Development Authority.

A Clear Step Forward

With its technologically advanced operating and control system, the Webster Water Treatment Project is an extremely efficient plant, and its state-of-the-art security measures and equipment reduce our vulnerability to natural occurrences such as main breaks or even natural disasters.

In short, the project represents a major step forward in our ability to serve customers – and the region – by supplying safe, reliable and affordable water. It has been in our future for a long time. As of 2013, it is a welcomed reality.